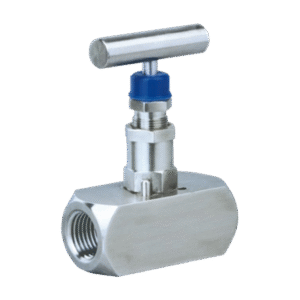

Needle Valve

Proflow Valves offers high-precision Needle Valves engineered for general instrumentation and flow regulation applications. Our needle valves are carefully machined to deliver accurate control, reliable shut-off performance, and long operational life. Designed with a compact and robust structure, these valves are ideal for a wide range of industrial uses where precision and durability are essential.

Proflow Needle Valves are available in multiple pressure ratings, including 150 psi, 300 psi, 1000 psi, 3000 psi, 6000 psi, and 10,000 psi, making them suitable for both standard and high-pressure instrumentation systems. Their unique design ensures consistent flow regulation and leak-free operation, even in demanding environments.

Choose Proflow Valves for superior-quality instrumentation needle valves that deliver accuracy, reliability, and performance across diverse industrial applications.